Ultrassay® Freeze Dryer is widely applied in pharmaceutical industry, biotechnology industry, biological science industry, materials science industry, chemical industry, food and agriculture industry etc. It is used to produce vaccine, drugs and permanently store biological tissues/organs.

Meet Different Demands

- Ultrassay® laboratory-scale freeze dryers are designed for two condensing temperatures: -70℃ and – 90℃.

- 5 types for each temperature, thus realizing 10 models in total as our offer for the laboratory scale.

- Desktop and compact design, featuring brilliantly small footprint as well as unsurpassed easiness to move.

- Informational recording operations grant the export of data for storage and any other purposes.

- The one-press-starting setup goes with standard types and optional upgrades.

- To cater to higher capacity and lower vacuum degree demands, Ultrassay is presenting a pilot-scale type for the option.

- Besides that, a better-upgraded machine is guaranteed by a stronger freezer dryer and vacuum pump, as well as other handy functions.

- Heated by two ways of electrical heating and silicone oil heating, you get one more choice now.

- Under the automatic programming procedures, computer software, and digital touch screen, you can control up to 40 temperature zones.

Freeze Drying Process

Freeze-drying, also called lyophilization or cryodesiccation, is the process of dehydration in a low temperature and vacuum environment by sublimation, unlike the way by conventional water evaporation by heating.

Lyophilization or freeze-drying is the gentlest way of all. The physical phenomenon of sublimation means a direct transition from the solid-state to the vapor state, bypassing the liquid state. The frozen product is therefore dried under a vacuum.

Usually, the vacuum concentration and freeze-drying are combined together to process the freeze-drying. In this way, those thermally sensitive materials can be well preserved.

Drying Method

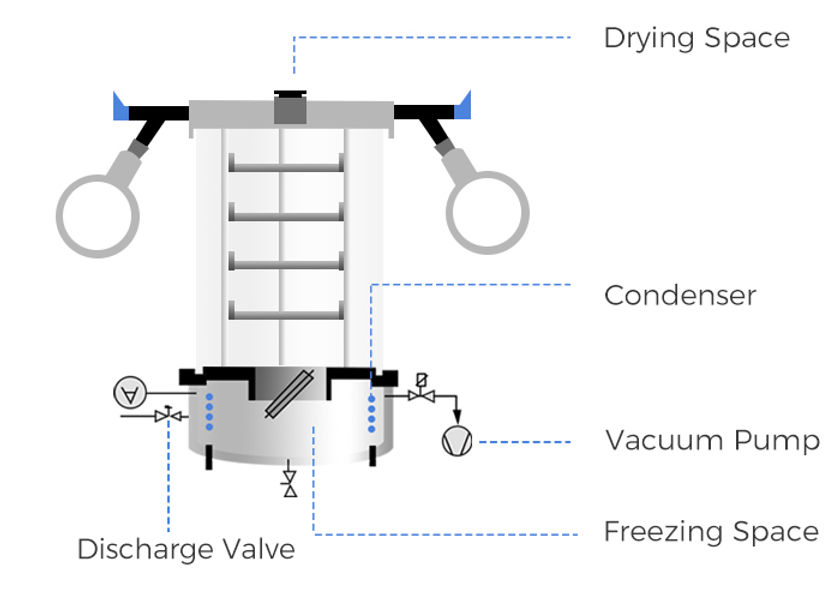

Double-chamber method

With this configuration, the material is separately pre-frozen and then dried above the condenser chamber. By the advantage of double chamber method, a discharge valve is equipped to separate the product chamber from the condensing chamber for the pressure increase test to determine the drying point.

Popular Applications

Gentle drying is very important for foods drying. Freeze drying make the preservation of their most flavor, color, texture and nutrition, and it can be stored for very long time.

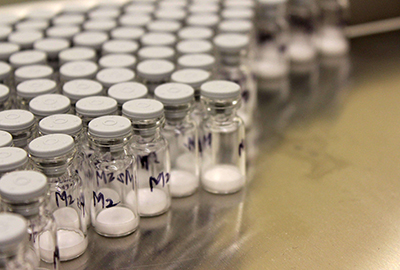

Pharmaceuticals are another subject that uses a lot of freeze drying technology. By maintaining the active performance and stabilization of those materials, freeze drying is often involved in this.

Biochemicals often refers to genetically modified medical substances, which are very complex. Freeze drying technology is introduced because of their sensitivity to temperature.

Request for quotation