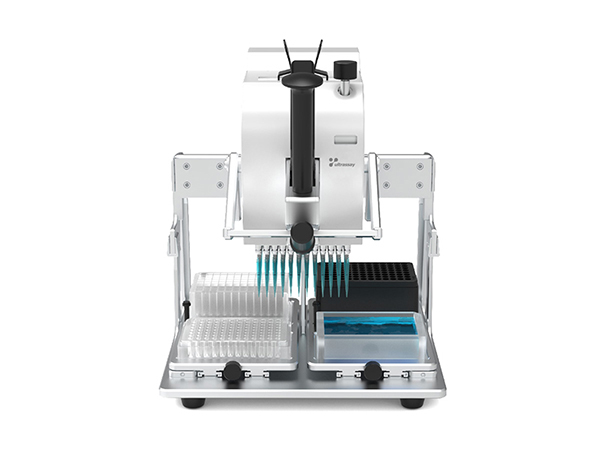

Fully Automated Liquid Dispensing System consists of Auto-stacker, Autofilling S200 and the integrated base. it is widely used to biology, medicine, genomics, and proteomics etc. Provides reliable automatic liquid dispensing solutions for laboratories and researches.

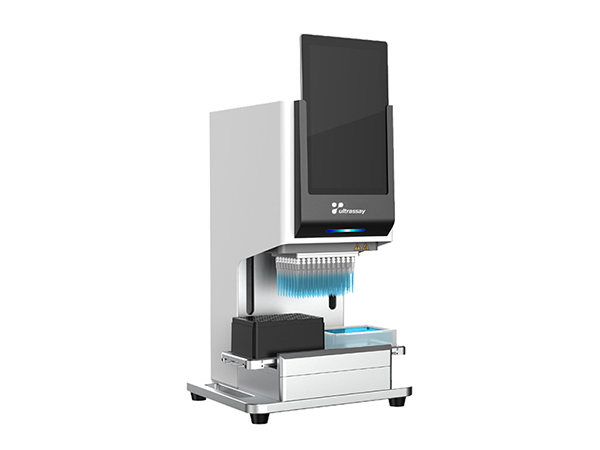

- 5-inch color touch screen, equipped with special dispensing integrated control software, effectively improves dispensing efficiency;

- Contains liquid separation and exhaust functions to facilitate liquid replacement and pipe cleaning;

- Programmable to support gradient dispensing, and the dispensing volume of each row of holes can be customized;

- Dispensing range 10-5000µL;

- Typical dispensing CV is 1.5%;

- Can be integrated with external Auto-stacker;

- Using a syringe to dispense liquids, the system is stable and reliable;

- Chinese and English interface, easy switching;

- Suitable for 24, 96 and 384 well standard microplates and deep well plates;

- Low-maintenance design, one-click to choose to work with or without a Auto-stacker;

- Users can choose three different dispensing speeds: “high/medium/low”, suitable for various dispensing applications from low speed to high speed;

The Autofilling S200 employs a high-precision injection pump, which can distribute liquids into various containers (24-well plates, 48-well plates, 96-well plates, 384-well plates and 1.5ml/ 2.0ml centrifuge tube). The whole process is automated, easy and accurate, It is suitable for dispensing various reagents and adding liquids for batch experiments. Replaces mechanical & electric single-channel and multi-channel pipettes.

S200 is easy to operate and can be an alternative device of Biotek’s Microfill and Thermo Fisher’s Multidrop system, that providing a trustworthy automatic liquid dispensing solution in drug R&D, genomics, proteomics, etc.

The Auto-stacker is a device specially used for automated processing of microplates. The Auto-stacker can be used with a variety of microplate dispensers Autofilling S200, Biotek’s microfill, Thermo Fisher’s Multidrop system, and Used in combined with a film sealer. it provides batch microplate processing capabilities.

- Compatible with a various microplates and deep-well plates;

- Easy to program, operate and integrate;

- Ability to use microplate from different manufacturers;

- Sturdy structure and reliable use;

- Can handle plates with or without lids (optional lid lift function);

- Communicate via RS232 interface;

- Equipped with special application driver;

- With Restack function, the plate can be restored to its starting position.

| Model | Autofilling-Robot | Autofilling-S200 | Autofilling-C100 |

| Applicable Container | 24, 48, 96, 384-well microplates, deep well plates etc. | ||

| Robot Arm | Yes with Auto-stacker | No (upgradable) | No |

| Display | 5’’ inch touch screen | ||

| Gradient Dispensing | Support | ||

| Capacity | 10~5000μL | 10~5000μL | 10~2500μL |

| Min. Increment | 1μL | 1μL | 1μL |

| Dispensing Speed | High/Middle/Low | ||

| Dispensing Time | <20s | <20s | 11s |

| Accuracy | ± 1μL @ 10μL

± 1μL @ 20μL ±1% @>100μL |

||

| CV | <5% CV @10μL

<2.5% CV @20μL <1% CV @>100μL |

||

| Max. Plate Qty | 50pcs 96-well microplate

72pcs 384-well microplate 14pcs 2.0ml DWP |

1pc 96-well microplate

or 384-well microplate or 2.0ml DWP |

1pc 96-well microplate

or 384-well microplate or 2.0ml DWP |

| Noise | ≤60dB | ||

| Air Flow | 50L/min | ||

| Air Input Pressure | 5.5bar (80PSI) ~ 5.7bar (87PSI) | ||

| Power Supply | 110V~220V 50/60Hz | ||

| Power Rate | 0.2Kw | 0.1Kw | 0.1Kw |

| Dimension | 970x687x938mm | 330x400x150mm | 293x332x140mm |

| Weight | 35kg | 7.5kg | 6.5kg |

| Working Enviroment | 10~40°C, 80%RH | ||

Request for quotation