| 37 |

Display |

7-inch high sensitive touch screen. |

| 38 |

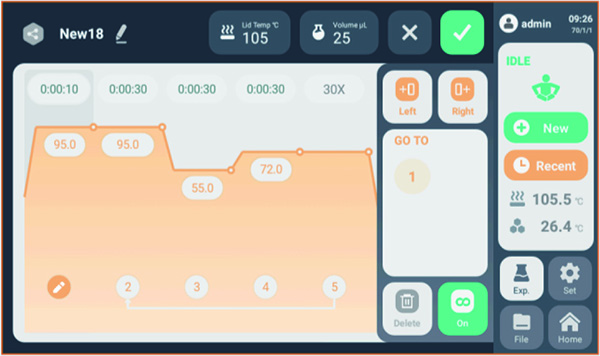

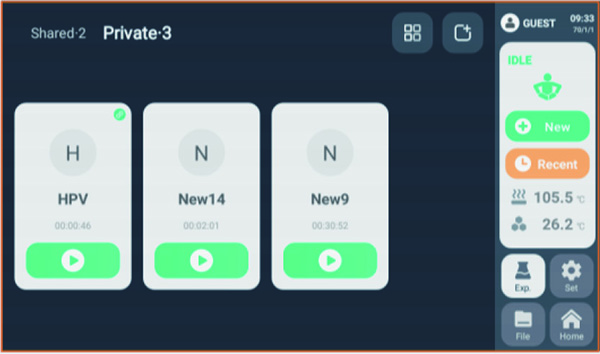

User friendly interface |

Yes. Dynamic water wave progress bar, animated operating status, breathing light indication, buzzer prompt. |

| 39 |

Screen lock |

For large-scale users, to prevent accidental operation or manual termination by others during operation, non-guest 39 users can lock the screen with a password and unlock it to operate the device. |

| 40 |

Easy interfaces switch |

Simple main interface, operating interface, dynamic curve, engineering interface. |

| 41 |

Inhibit Non-specific amplification |

Yes, Before running the cycle program, the block is cooled to 10°C until the hot lid temperature get set value during hot lid warming up. |

| 42 |

Tube mode |

Yes, Precise control according to reagents volume. |

| 43 |

Adaptive lid |

Auto adapts to various heights of tubes (high/low/flat top/dome tube). |

| 44 |

Smart gradient |

Yes, Dynamic power control ensures that the temperature of each column reaches the target synchronously. |

| 45 |

Self-test when power on |

Yes |

| 46 |

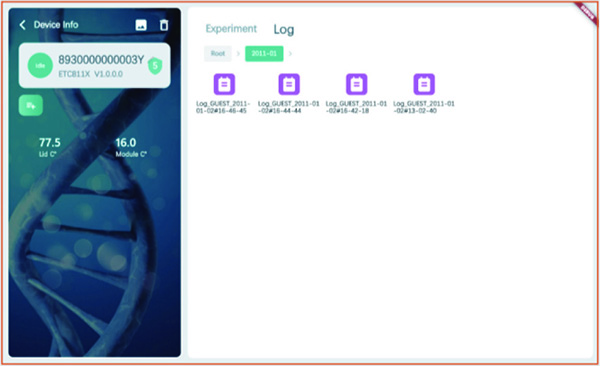

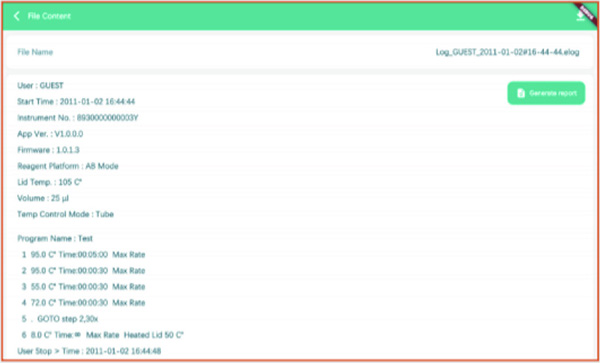

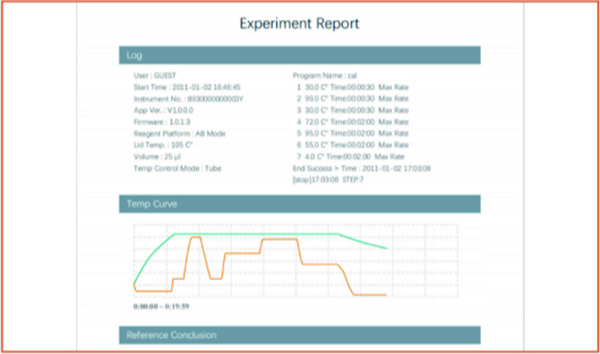

Auto report after running |

Yes |

| 47 |

Self-diagnosis and report |

Yes |

| 48 |

Soaking after running |

Yes, The lowest soaking temperature is 0°C. |

| 49 |

Memory function of power-down |

Yes |

| 50 |

Total time / Remain time prediction |

Yes |

| 51 |

Peltier life warning |

Yes, assess Peltiers health status automatically and give maintenance suggestions. |

| 52 |

Block temperature calibration |

Yes, Engineering mode only. |

| 53 |

Key tone |

On/off |

| 54 |

Screen brightness adjustment |

Yes |

| 55 |

System |

Includes system configuration, self-test, factory setting, software upgrade, engineering interface (Engineering mode only) |

| 56 |

Help |

Product features, software features, quick guide, troubleshooting, contact information. |

| 57 |

Interface language |

Chinese / English switch freely. |

| 58 |

One-click Incubation |

A quick incubation program is permanently resident on the home page, can be started with one click, and temperature and time parameters can be edited.

|

| 58 |

Heating Lid Preheating |

The preheating temperature can be set, and the heating lid temperature is maintained when idle to reduce experimental time. |

| 60 |

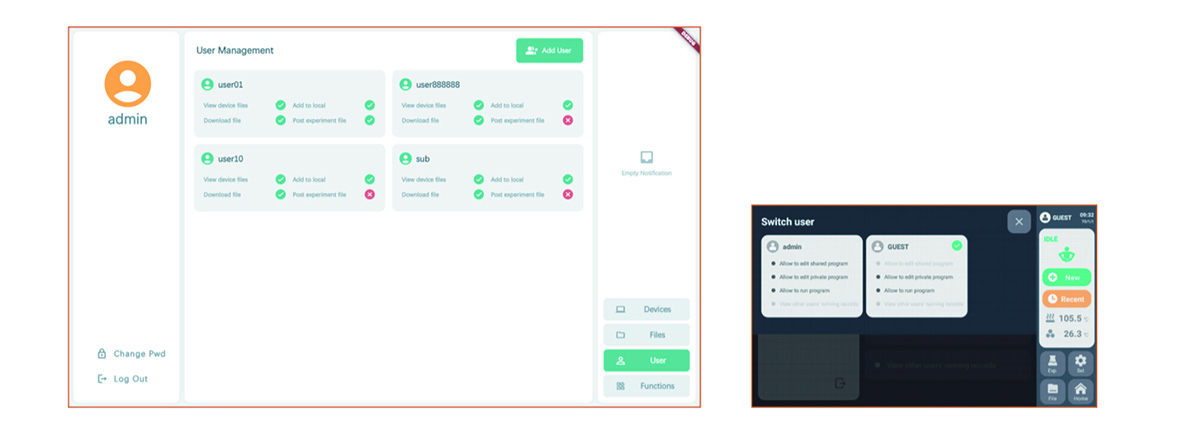

Configurable Guest Mode |

The administrator can turn off the guest mode, and after turning it off, users must log in to use the device. |

| 61 |

Cluster Control |

Multiple devices can be monitored for status, programs can be issued, plans can be set, reports can be generated, and batch screen locking/unlocking can be performed on the computer side. |